Does the Cool touch fabric produced by the company use advanced weaving technology? What innovative technologies are used in the production process of this fabric?

1. Application of advanced weaving technology

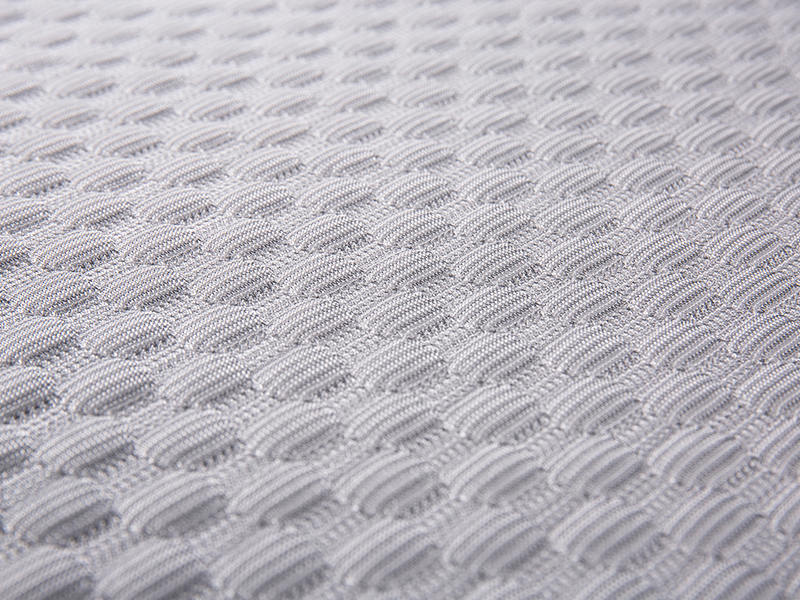

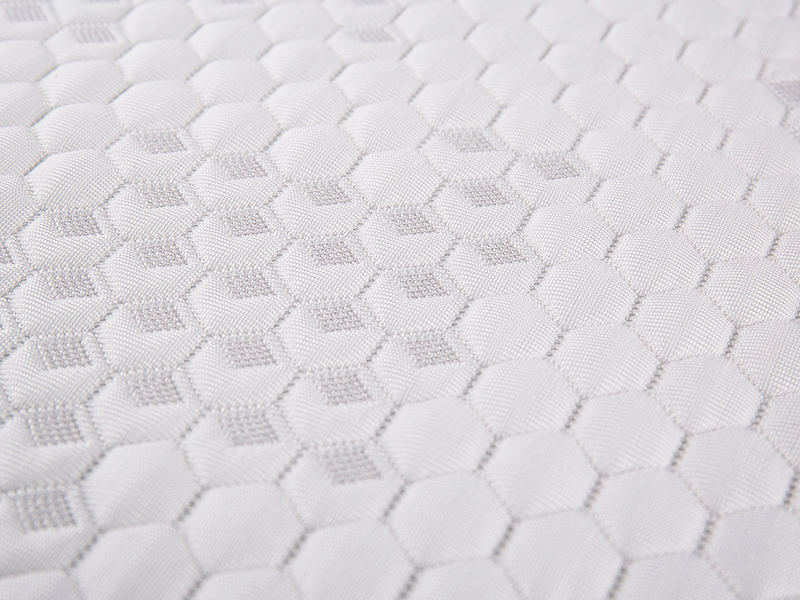

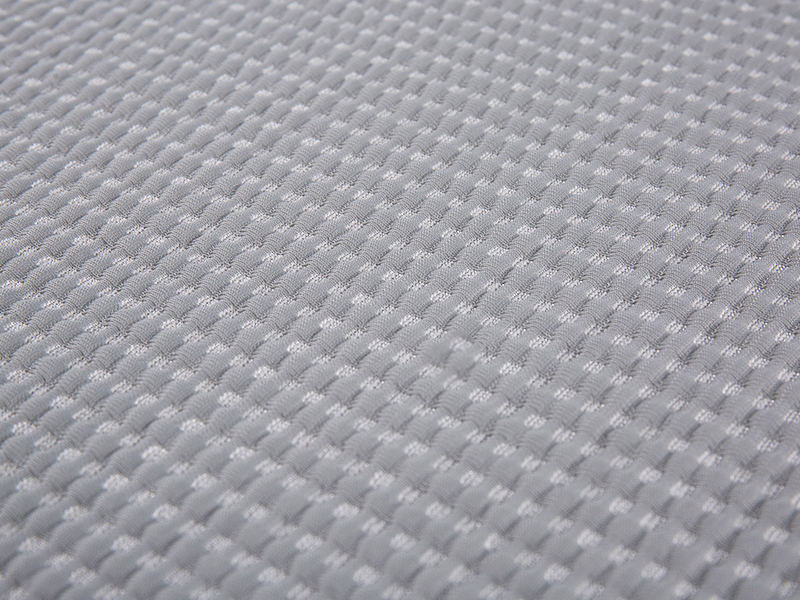

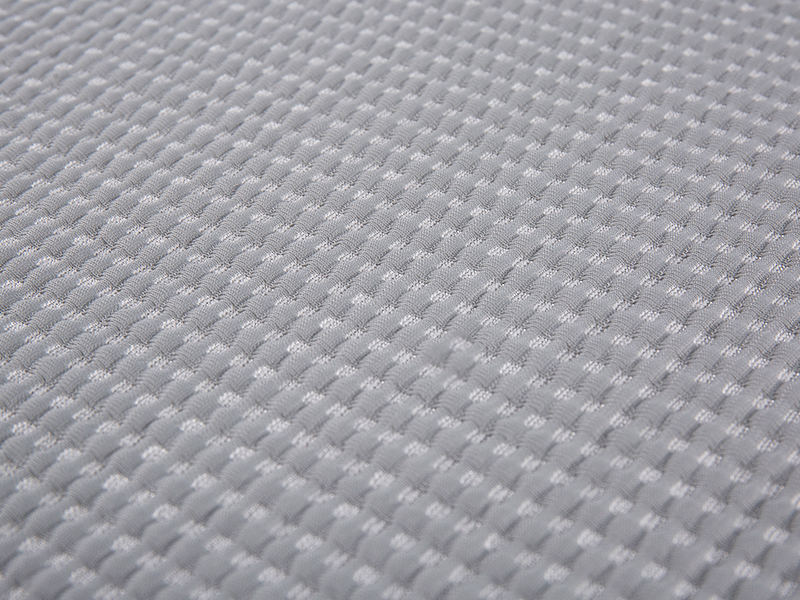

High-precision weaving equipment

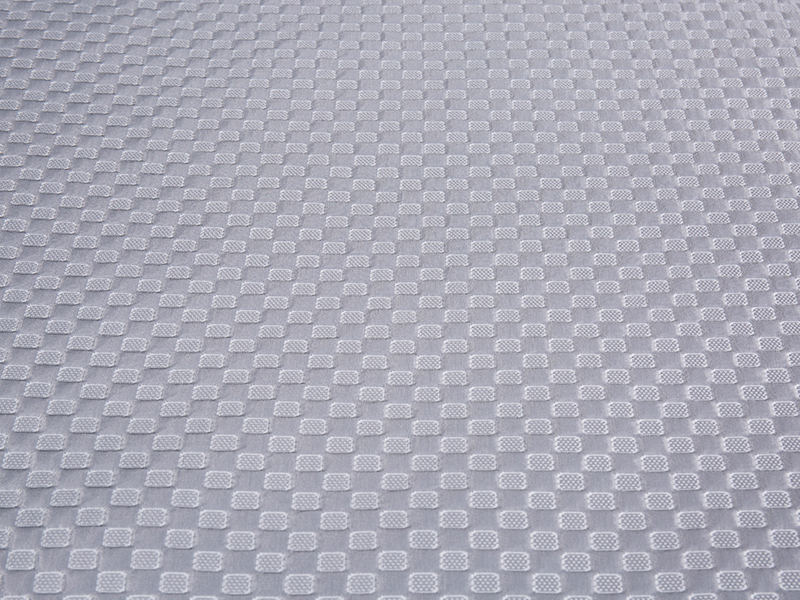

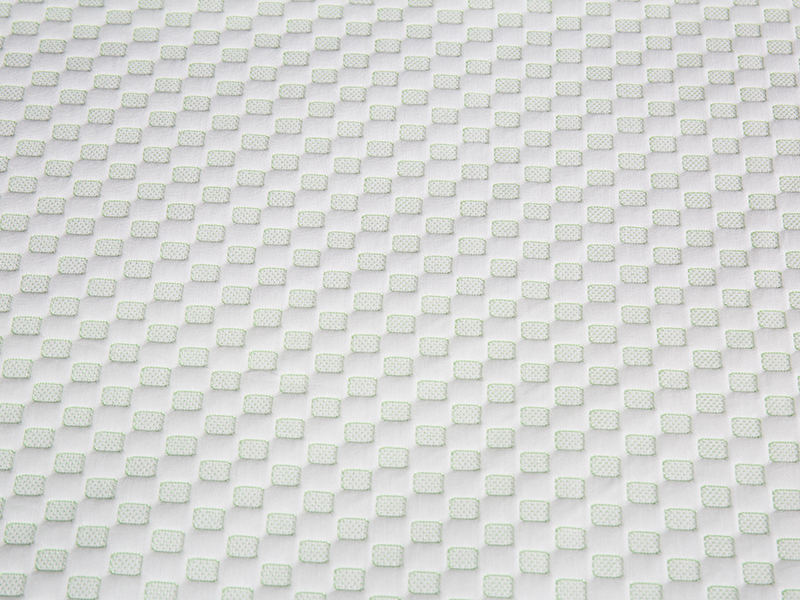

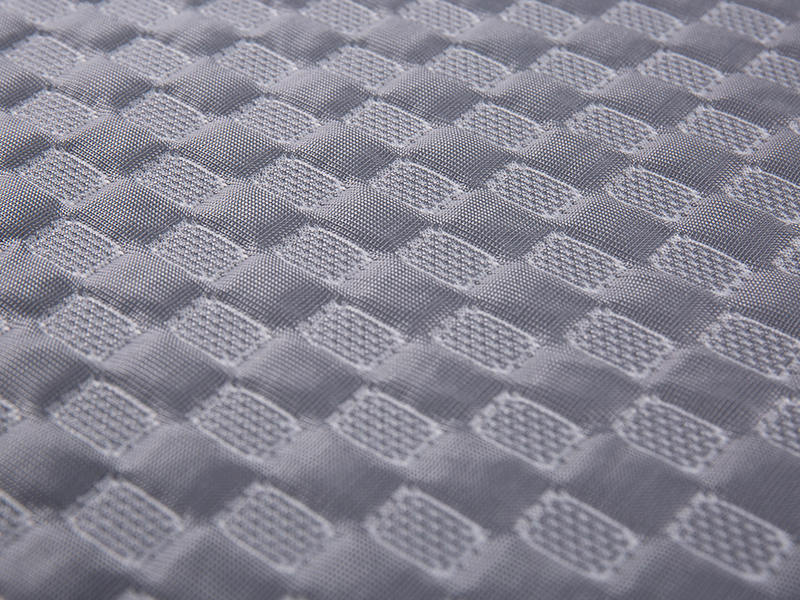

In order to produce high-quality Cool touch fabric, Hangzhou Xiaoshan RongLi Clothing Co., Ltd. has introduced advanced high-precision weaving equipment from West Germany, Italy and other countries. These equipment can achieve more sophisticated weaving processes and ensure the fine processing of the weaving density, texture and touch of the fabric. Through high-precision control, every inch of the fabric can achieve a uniform effect, avoiding the uneven thickness and pulling problems that may occur in traditional production, thereby improving the comfort and durability of the fabric.

Intelligent weaving process

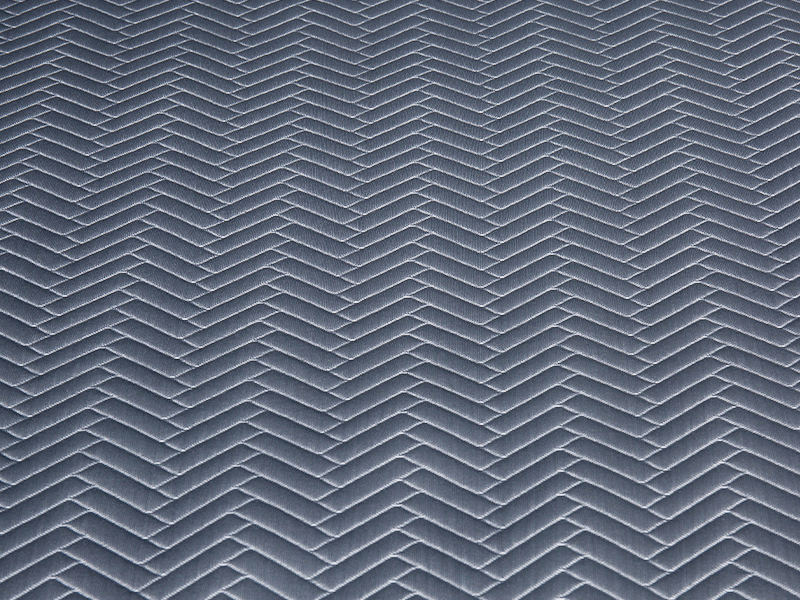

The company focuses on the application of digital and intelligent technologies, and introduces automated and intelligent weaving equipment in the production process of Cool touch fabric. These equipment can automatically adjust the weaving parameters according to the needs of the fabric, and achieve fine temperature control and material optimization. For example, the CNC machine tools and automated control systems used can accurately control the line density and fabric structure during the weaving process to ensure the breathability, cooling effect and touch consistency of the fabric.

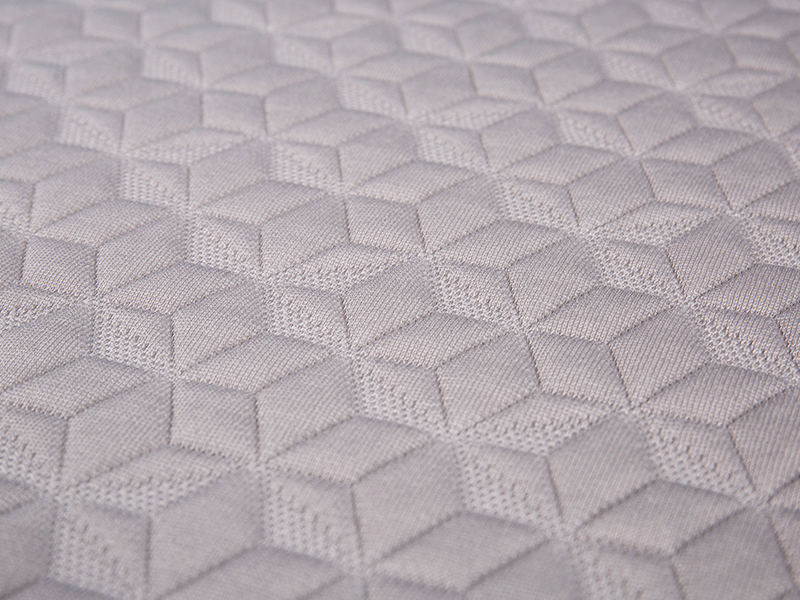

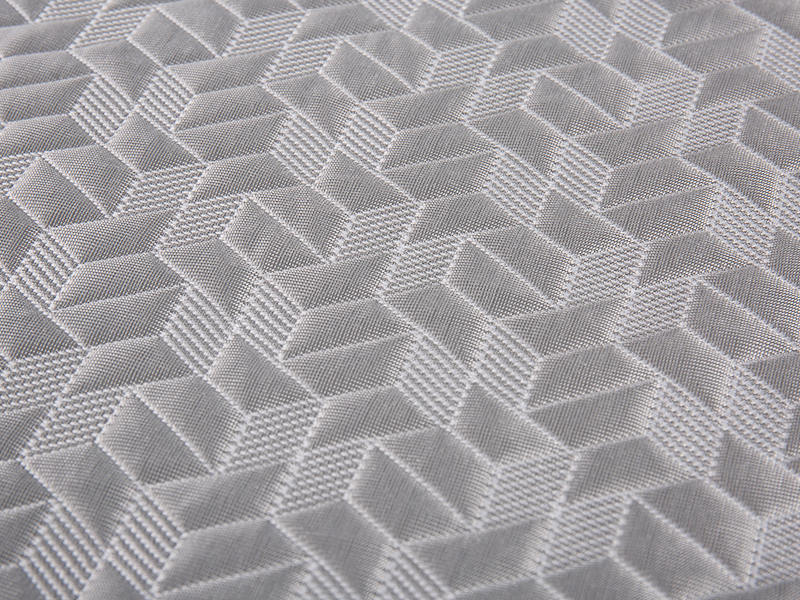

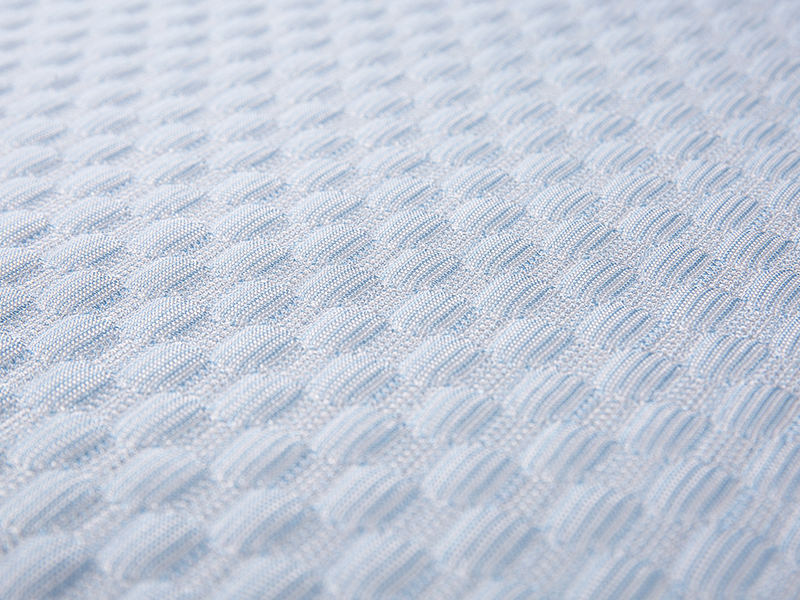

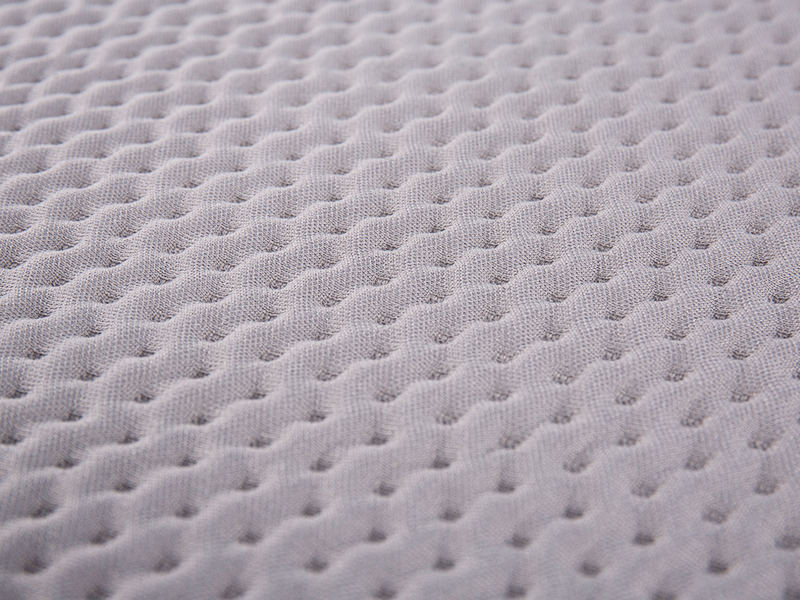

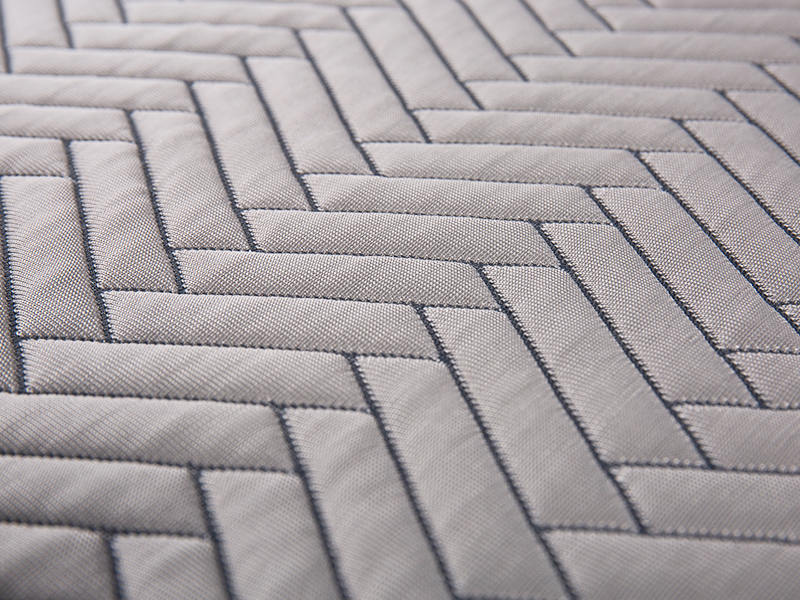

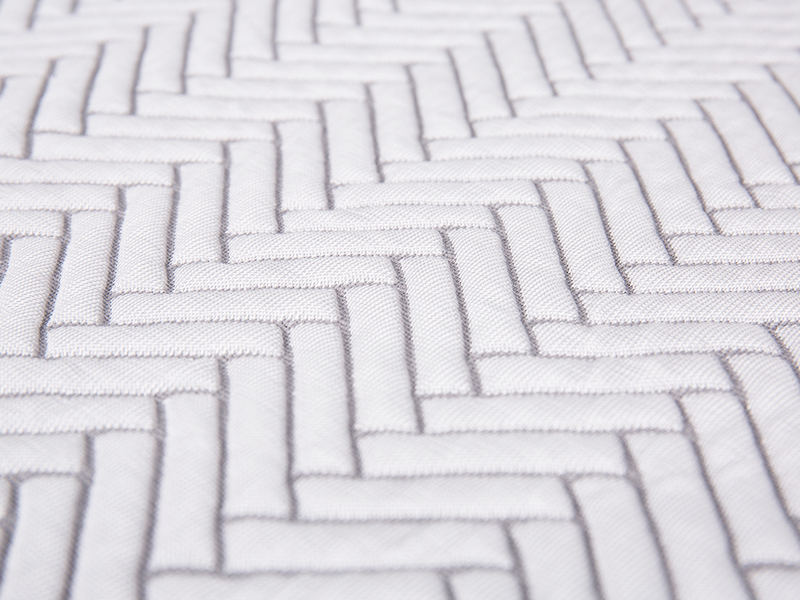

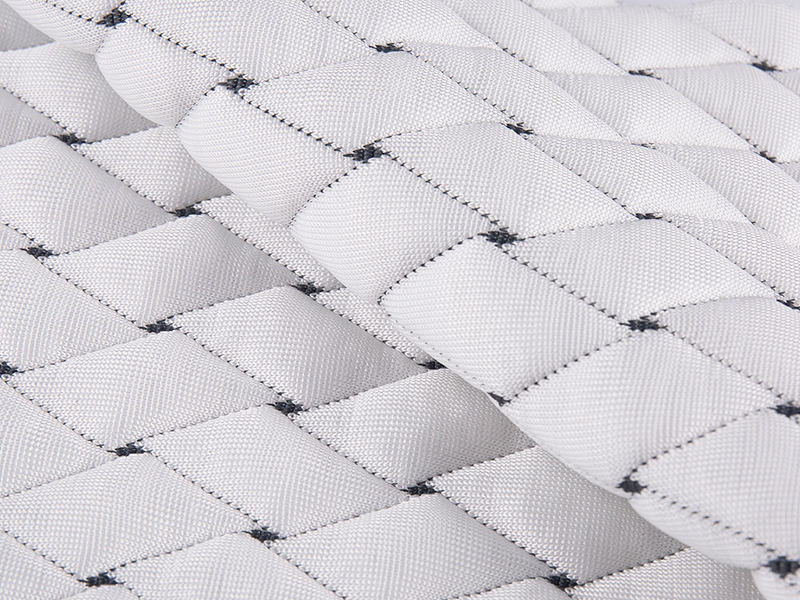

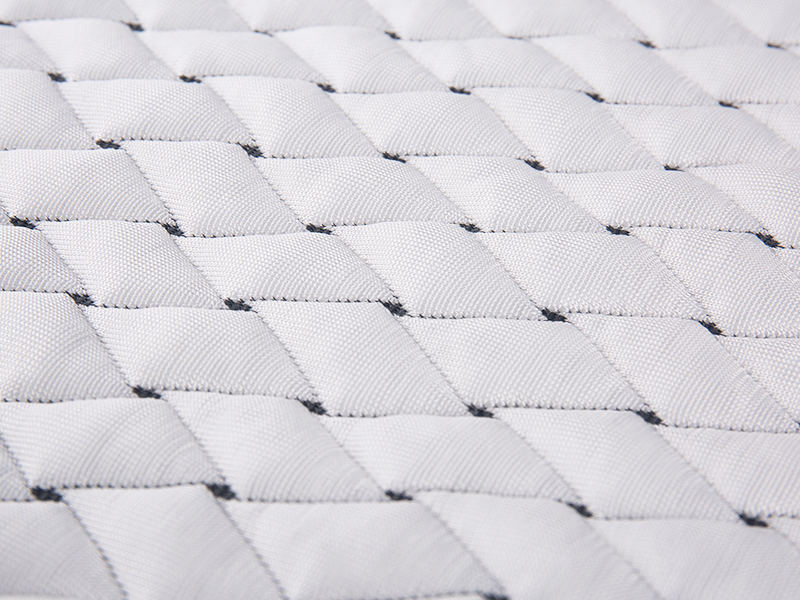

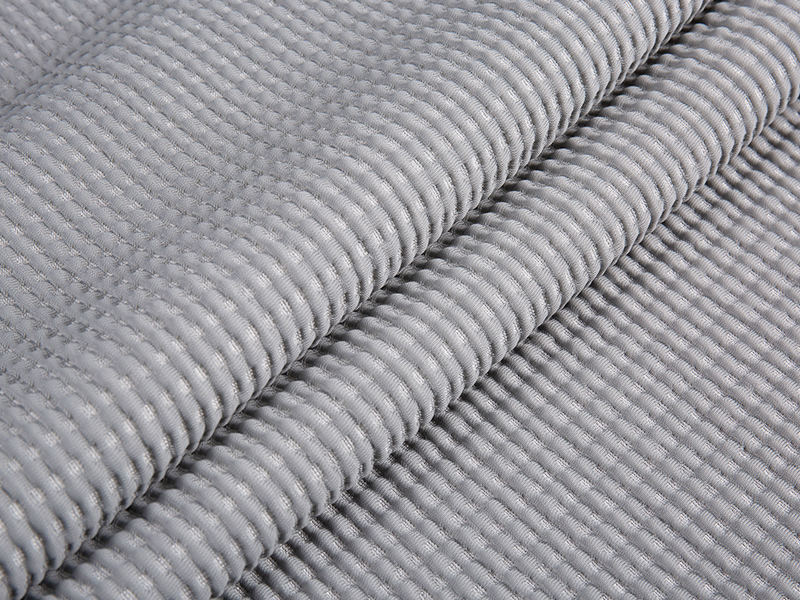

Multi-layer weaving technology

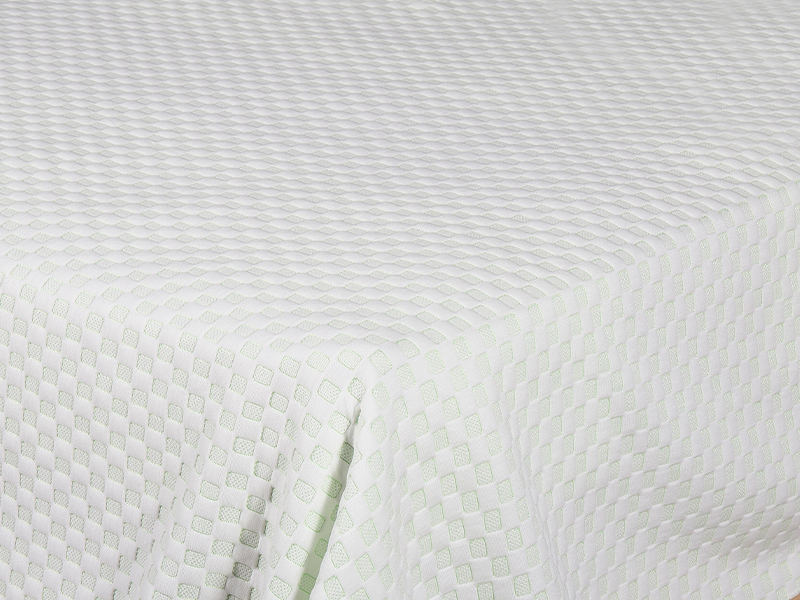

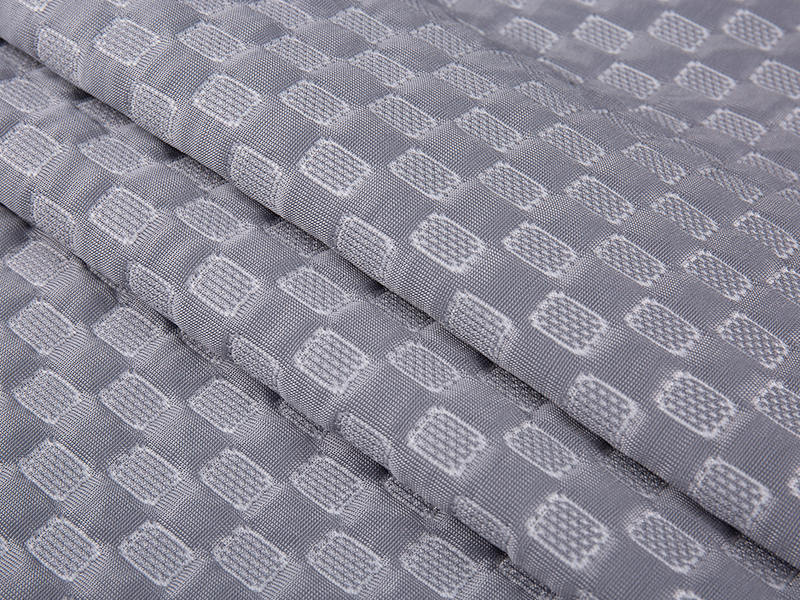

The company uses multi-layer weaving technology to create Cool touch fabric with excellent air permeability and moisture absorption. This technology interweaves layers of different fiber materials together, allowing the fabric to effectively regulate temperature and humidity. The outer layer usually uses cool fiber materials, which can quickly absorb moisture and take away heat through evaporation to keep the skin surface dry; the inner layer uses highly breathable materials to effectively remove moisture and ensure the breathability and comfort of the fabric. The application of this technology not only improves the functionality of the fabric, but also enhances its comfort.

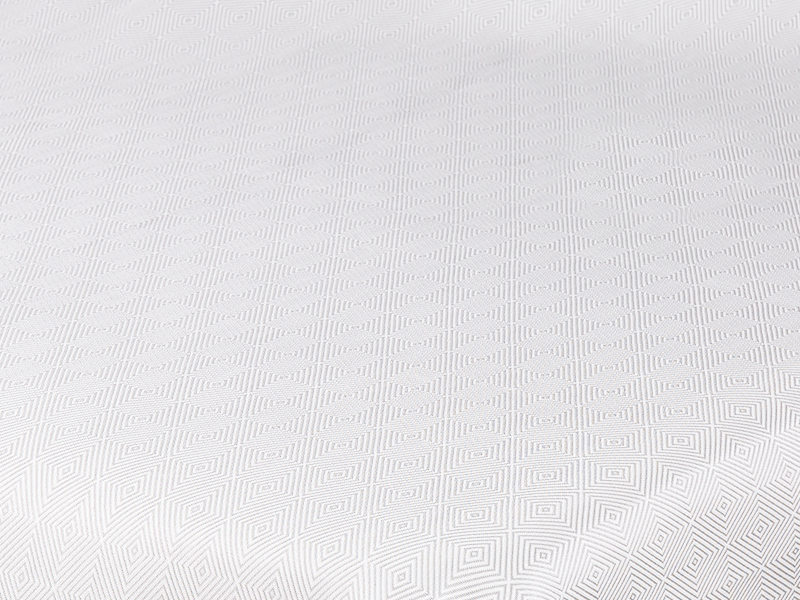

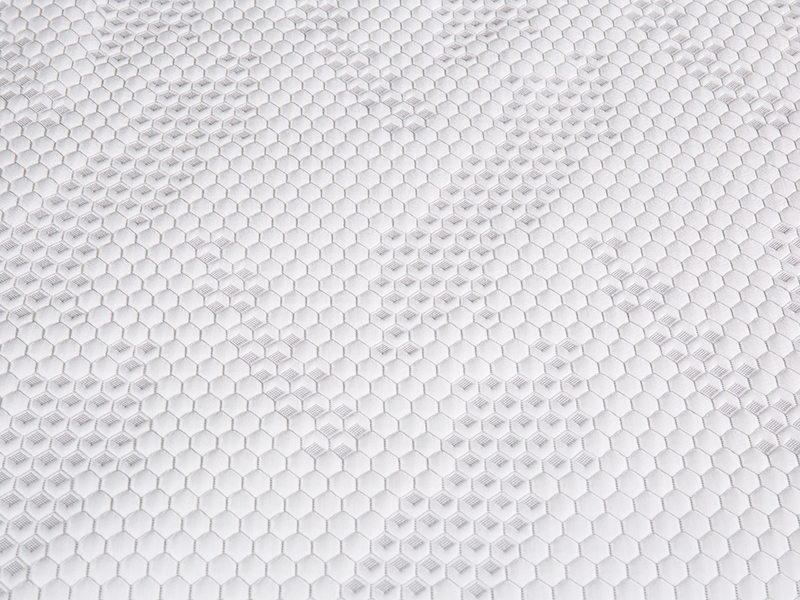

Nanotechnology and microfiber application

In the production process of Cool touch fabric, the company also applied nanotechnology and microfiber technology. These technologies can form tiny nano coatings on the surface of the fabric to improve the cooling function of the fabric. Nano coatings can effectively enhance the thermal conductivity of the fabric, giving it a better temperature control effect. In addition, the use of microfibers improves the softness and touch of the fabric, making the Cool touch fabric more comfortable and delicate, as if it is skin-friendly, greatly improving the consumer experience.

2. Application of innovative technologies

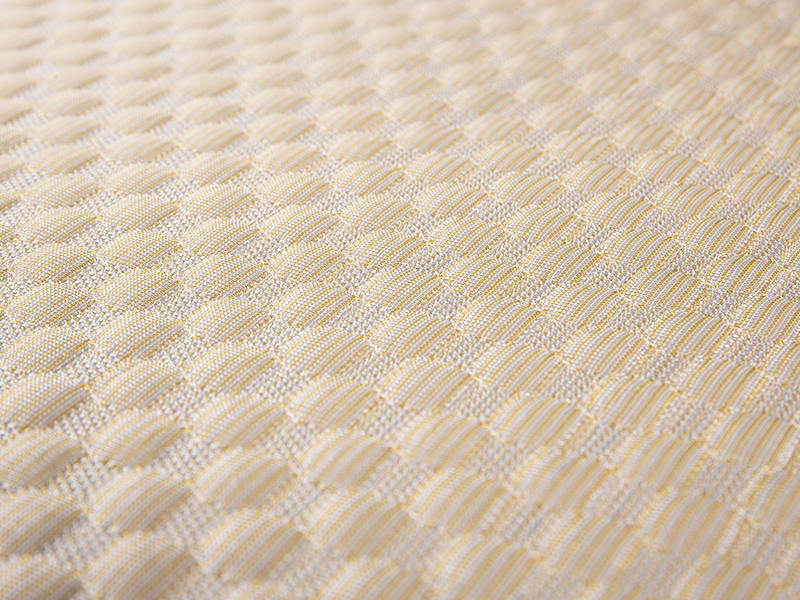

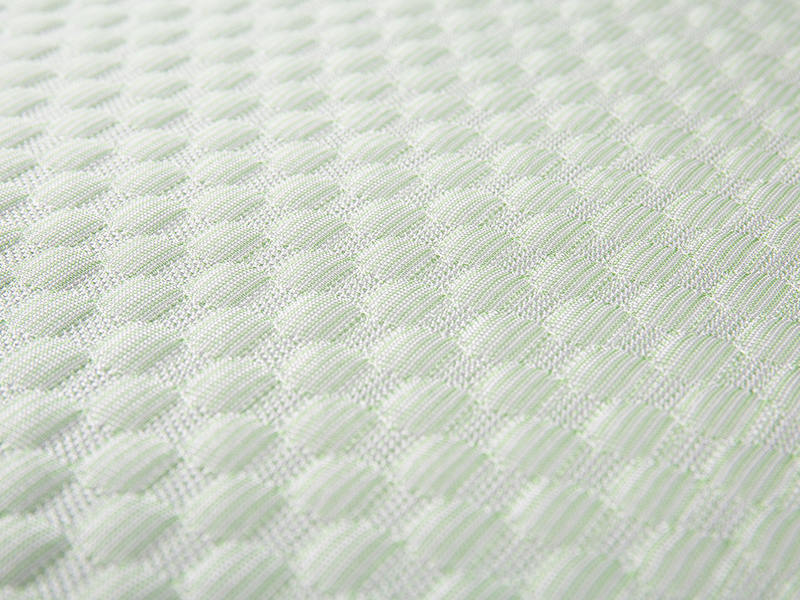

Research and development and application of cool touch fibers

Hangzhou Xiaoshan RongLi Clothing Co., Ltd. has been continuously exploring and applying cool fiber technology through independent research and development and cooperation with domestic and foreign scientific research institutions. This fiber material has good moisture absorption and thermal conductivity, can quickly take away heat when it contacts the skin, and produce a cool effect. The company selected special fibers with high thermal conductivity and low thermal conductivity, and added these innovative materials during the textile process of the fabric, so that the fabric has a lasting cool performance. The application of cool touch fibers enables "Cool touch fabric" to maintain a lower temperature in a hot environment, ensuring that consumers enjoy a refreshing and comfortable experience in home textile products such as mattresses, pillowcases, and sofas.

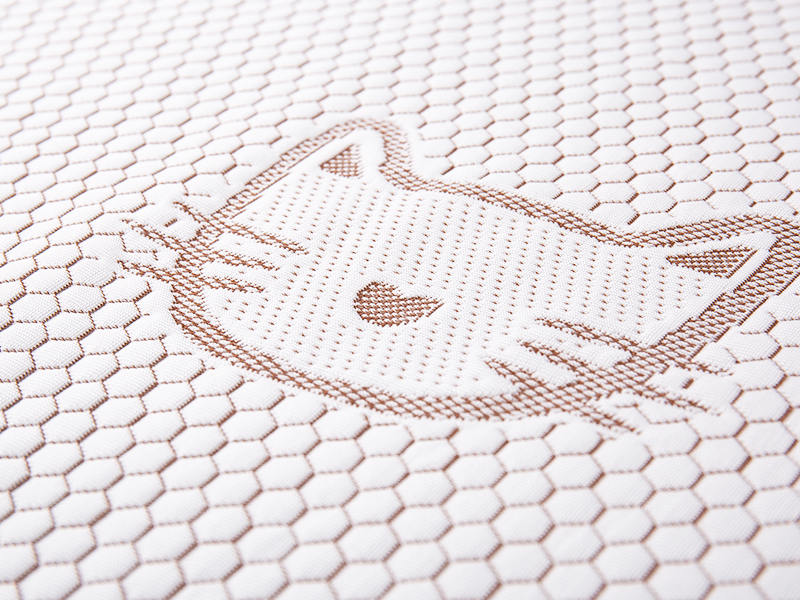

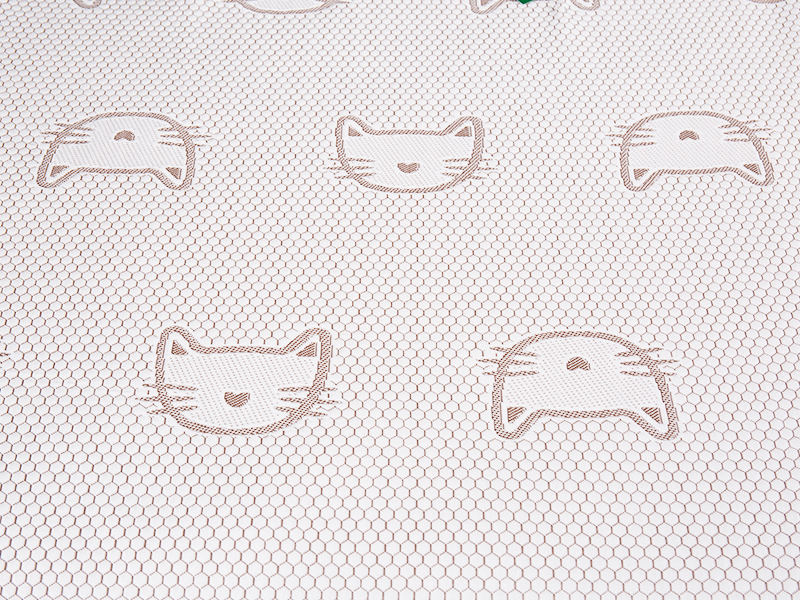

Combination of heat transfer printing technology

In order to enhance the appearance and personalization of Cool touch fabric, the company also combined heat transfer printing technology. Heat transfer printing can give the fabric a variety of color and pattern options while ensuring the functionality of the fabric, making it more in line with the modern consumer's demand for personalized and fashionable home textile products. Heat transfer technology further enhances the market competitiveness of the product by forming tiny printed patterns on the surface of the fabric without destroying the breathability and cooling function of the fabric.

Sustainable development and environmental protection technology

As a company focusing on sustainable development, the company is committed to the application of environmental protection and energy-saving technologies in the production process of Cool touch fabric. By adopting low-energy and pollution-free production processes, the company ensures that the impact of fabrics on the environment during the production process is minimized. In addition, all fabrics produced comply with environmental protection standards such as EU REACH and German Oeko-Tex Standard 100, ensuring that the products are harmless to consumers' health and can be recycled and reused.

Antibacterial and deodorant technology

In the process of producing Cool touch fabric, the company also added antibacterial and deodorant technology to enhance the added value of the fabric. By adding antibacterial ingredients to the fabric, Hangzhou Xiaoshan RongLi Clothing Co., Ltd. effectively reduces the growth of bacteria and odors, especially in home textile products such as mattresses and pillowcases, which can better keep the fabric fresh and hygienic. The application of this technology enhances the functionality of the fabric, allowing it to provide higher hygiene protection on the basis of comfort.