What kind of knitting process is used for bamboo knitted mattress fabrics? Such as weft knitting, warp knitting, etc. How to control the density and elasticity of the fabric during the weaving process?

Among the company's many products, bamboo knitted mattress fabrics stand out with their unique natural comfort and environmental protection characteristics, becoming a highlight in the market. This fabric mainly uses rayon made from bamboo as the fiber raw material, making full use of bamboo, a rapidly renewable resource, which not only conforms to the environmental protection concept of modern society, but also brings consumers an unprecedented sleep experience.

In terms of knitting technology, RONG LI Company finally decided to use weft knitting technology to produce bamboo knitted mattress fabrics after in-depth research and repeated experiments. The weft knitting process, with its high efficiency and flexibility, can well adapt to the characteristics of bamboo fibers, ensuring that the fabric has good elasticity and durability while maintaining softness, breathability and moisture absorption and perspiration performance.

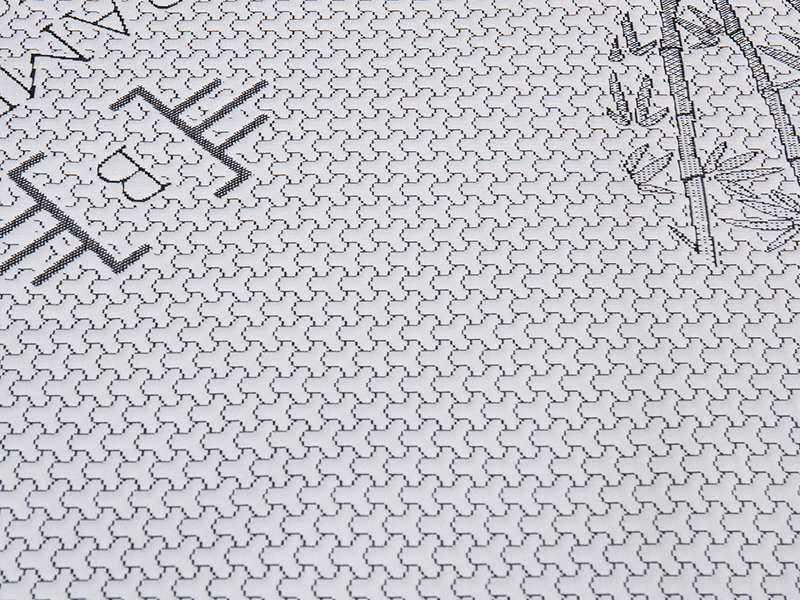

The weft knitting process mainly forms fabrics by interweaving weft yarns and warp yarns, in which the weft yarns move back and forth along the width of the loom during the weaving process, while the warp yarns remain fixed. This process makes the fabric have good elasticity in the transverse (weft) direction, which can well adapt to the curves of the human body and improve the comfort of sleep. At the same time, the weft knitting process can also accurately control the physical properties and appearance of the fabric by adjusting the thickness, density and interweaving method of the yarn to meet different usage requirements.

During the weaving process, RONG LI uses advanced weaving technology and precise control systems to ensure the uniformity of fabric density and the rationality of elasticity. First, in the yarn preparation stage, the company will strictly screen qualified bamboo rayon to ensure that its fiber length, strength and fineness meet production requirements. Then, in the weaving process, the uniformity and stability of the fabric density are ensured by accurately controlling the tension of the yarn, the feed amount and the running speed of the loom.

In order to control the elasticity of the fabric, RONG LI uses a variety of technical means. On the one hand, by adjusting the interweaving density and angle of the weft and warp yarns, the elastic modulus and recovery performance of the fabric are changed. On the other hand, by adding an appropriate amount of elastic fiber (such as spandex, etc.) to the yarn, the overall elasticity and comfort of the fabric are improved. At the same time, the company also uses advanced post-processing processes, such as relaxation treatment and shaping treatment, to further stabilize the elastic properties of the fabric and ensure that it is not easy to deform or relax during use.

In the process of producing bamboo knitted mattress fabrics, RONG LI has fully utilized its technical advantages and quality assurance capabilities. The company not only has advanced weaving machinery and testing equipment, but also has established a complete laboratory system, which can conduct comprehensive and accurate testing and analysis of various performance indicators of fabrics. At the same time, the company has also passed ISO9001:2000 quality system certification, EU REACH testing and German Heinstein Oeko-TexStand100.xStand100 certification and other multiple quality certification systems to ensure the quality and safety of the products.

In the process of fabric production, RONG LI always follows the principles of environmental protection and health, and strictly controls the source of raw materials and the process of production technology. The bamboo rayon used by the company not only has excellent natural comfort and environmental protection characteristics, but also can be further improved through advanced processing technology. Its quality and performance. At the same time, in the post-processing process of the fabric, the company also uses environmentally friendly dyes and auxiliaries, and strictly controls the discharge of wastewater and exhaust gas to ensure the environmental protection and sustainability of the product.

In order to meet the needs of different consumers, RONG LI also provides a variety of weaving methods for consumers to choose when producing bamboo knitted mattress fabrics. Among them, the cotton satin weave can bring an extremely soft and smooth feeling; the plain weave can bring a refreshing and cool feeling, suitable for summer use; and the twill weave can bring balance and durability, suitable for consumers who have high requirements for durability. These diverse weaving methods not only enrich the styles and styles of the products, but also provide consumers with more choices and customized services.