How to ensure the accuracy of patterns and shapes during the weaving of bamboo pillow cloth? How to control the tightness and uniformity of weaving?

In the production process of bamboo pillow cloth, RONG LI pays special attention to the accuracy of patterns and shapes, as well as the tightness and uniformity of weaving. These key factors directly affect the final quality and user experience of the product. Here are the specific measures on how we ensure these technical details:

Guarantee of pattern and shape accuracy

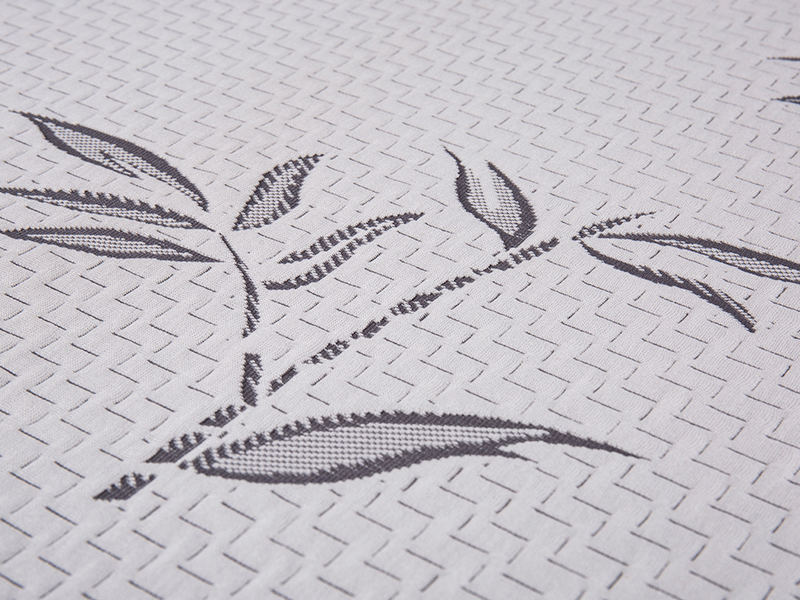

High-precision design and plate making: In the pattern design stage, we use advanced computer-aided design (CAD) systems to ensure the accuracy of patterns and color consistency. After the design is completed, the pattern is converted into a digital template that can be used for weaving through high-precision plate making technology. In this step, we use laser cutting and precision engraving technology to ensure that the template has smooth edges and accurate dimensions, laying a solid foundation for the subsequent weaving process.

Intelligent weaving control system: During the weaving process, RONG LI introduced an intelligent weaving control system that can monitor the warp and weft tension, weaving speed and pattern position of the fabric in real time to ensure that each weaving process is strictly carried out in accordance with the preset parameters. Through the built-in image processing algorithm, the system can instantly identify and correct pattern deviation or deformation, thus ensuring the accuracy of the pattern and shape of the final product.

Quality inspection and feedback mechanism: After weaving, we use high-precision scanners to inspect the quality of the finished product, focusing on the integrity, clarity and accuracy of the pattern. Once any deviation is found, it is immediately fed back to the production department for necessary adjustments and optimization to ensure that each batch of products can meet the highest standards.

Control of weaving tightness and uniformity

Precision tension control system: During the weaving process, the tension of the warp and weft is the key factor affecting the tightness and uniformity of the fabric. RONG LI uses an advanced tension control system that monitors and adjusts the tension of the warp and weft in real time through precise sensors and algorithms to ensure that it remains constant throughout the weaving process. This system not only improves the uniformity of the fabric, but also significantly reduces problems such as thread breakage and wrinkling caused by uneven tension.

Intelligent weaving program optimization: Our weaving machinery is equipped with intelligent programming functions, which can automatically adjust the weaving program according to different fabric types, pattern complexity and customer needs. By optimizing the weaving path, needle gauge and weaving speed, we are able to achieve the best balance between fabric tightness and uniformity while ensuring the accuracy of pattern and shape.

Multi-stage quality inspection: During the weaving process, we set up multiple quality inspection points to conduct a comprehensive inspection of the tightness, uniformity and appearance quality of the fabric. These inspection points include raw material preparation, pre-machine inspection, real-time monitoring during weaving, and final inspection of finished products. Through multi-stage and comprehensive quality control, we are able to detect and solve potential problems in a timely manner to ensure the excellent quality of the final product.

Innovative materials and processes: In the production of bamboo pillow cloth, we pay special attention to the selection of materials and innovation of processes. Bamboo viscose fiber (recycled bamboo fiber) has become our preferred raw material for its natural breathability, moisture absorption and perspiration, antibacterial and deodorizing properties. In the weaving process, we combine unique weaving techniques and filling materials (such as shredded memory foam, down substitutes, buckwheat, etc.), which not only improves the comfort and durability of the product, but also further enhances its environmental protection and sustainability.