How to ensure the uniformity and stability of blended or interwoven fabrics during the production of Tencel/Lyocell pillow fabrics?

Raw material selection and pretreatment

1. Selected raw materials

TENCEL™/Lyocell fiber, as a cellulose fiber derived from renewable eucalyptus, is known for its unique environmental friendliness, softness, breathability and moisture absorption. RONG LI strictly controls the selection of raw materials to ensure that each batch of Tencel/Lyocell fiber meets international environmental standards and has good physical and chemical properties, providing a solid foundation for subsequent blending or interweaving.

2. Pretreatment process

In order to improve the uniformity and stability of blended or interwoven fabrics, raw material pretreatment is crucial. RONG LI uses advanced pretreatment technology, including fiber relaxation, humidity regulation and anti-static treatment, to ensure that the fiber maintains the best physical state during subsequent processing and reduce fabric unevenness caused by differences between fibers.

Blending and interweaving technology

1. Precise proportioning and mixing

In the process of blending Tencel/Lyocell with other fibers (such as cotton, linen, etc.), RONG LI uses high-precision electronic scales to proportion the raw materials to ensure that the proportion of each fiber is accurate. At the same time, advanced fiber mixing equipment is used to fully and evenly mix different fibers through airflow or mechanical means, laying a good foundation for subsequent spinning and weaving.

2. Interweaving technology optimization

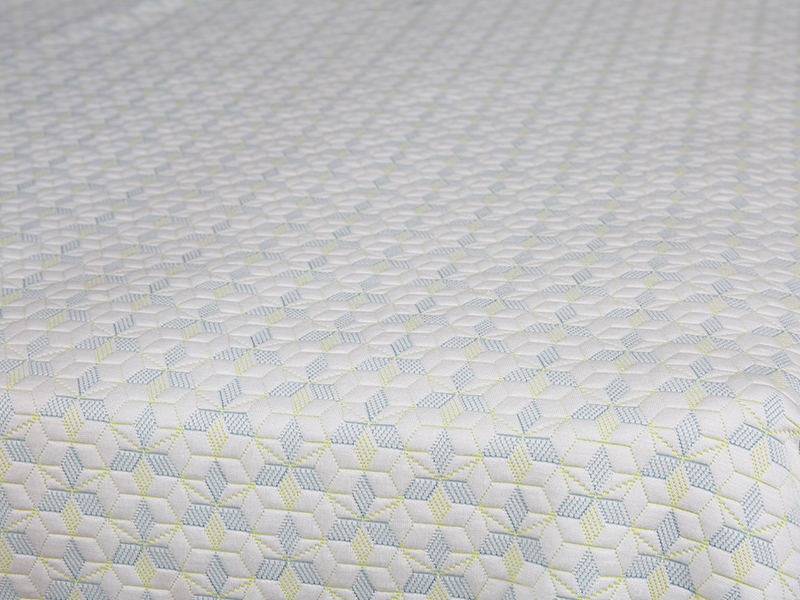

For interwoven fabrics, RONG LI uses advanced air-jet looms or rapier looms to ensure that Tencel/Lyocell fibers and other fibers form a stable and uniform structure during the interweaving process by accurately controlling the tension of the warp and weft yarns, the feeding speed and the position of the interweaving points. In addition, we have also developed unique interweaving processes, such as using multi-arm looms to achieve precise interweaving of complex patterns, further enhancing the visual beauty and structural stability of the fabric.

Fabric post-processing and quality control

1. Fine post-processing

Blended or interwoven fabrics need to go through a series of post-processing processes, including shaping, dyeing, finishing, etc. RONG LI uses environmentally friendly dyes and auxiliaries, combined with advanced dyeing processes such as overflow dyeing and airflow dyeing, to ensure that the fabrics are bright, uniform and have good fastness. At the same time, high-temperature setting treatment is used to enhance the dimensional stability and wrinkle resistance of the fabrics.

2. Quality Control System

RONG LI has passed ISO9001:2000 quality system certification, and all fabrics have undergone strict EU REACH testing and German Heinstein Oeko-Tex Standard 100 certification to ensure that the products meet international environmental protection and safety standards. In the fabric production process, we set up four testing links (samples, on-machine, woolen cloth, finished products), and each link is equipped with advanced testing equipment and professional testing personnel to conduct all-round quality monitoring of the fabrics. Especially in terms of the uniformity and stability of blended or interwoven fabrics, we use high-precision image analysis systems and physical performance testers to accurately measure and evaluate the fiber distribution, thickness, strength, air permeability, hygroscopicity, etc. of the fabrics to ensure that each product meets the highest quality standards.

RONG LI has always regarded technological innovation as the core driving force for corporate development. In the research and development of Tencel/Lyocell pillow fabrics, we not only focus on the optimization of traditional processes, but also actively explore the application of new materials. For example, we have successfully integrated environmentally friendly materials such as graphene, silver fiber, and negative ions into Tencel/Lyocell blended or interwoven fabrics. These new materials not only improve the antibacterial, deodorizing, and warm properties of the fabrics, but also give the fabrics more health functions, such as promoting blood circulation and improving sleep quality. Through the combination of new materials and advanced equipment, RONG LI has successfully created pillow fabrics that are both fashionable and healthy, meeting the modern people's pursuit of high-quality life.